Holiday Picks: A Fiber Engineer’s Wishlist

4th December, 2025

The holiday season is here – a time for celebration, reflection, and the annual challenge of finding the perfect gifts for the people who matter

The global shift from fossil fuels to electricity in so many sectors of our economy is leading to an increased demand for electric power. In the US, the Energy Information Administration (EIA) expects electricity consumption to increase by 2.4% compared to 2021. In the UK, McKinsey & Co. predicts that the electricity demand will increase by approximately 50% by 2035, and forecasts are similar for the rest of Europe, where demand is expected to grow consistently at a CAGR of about 2% until 2035.

To accommodate the need for more electricity, more power lines will need to be installed and connected to transmit and distribute electricity. Ensuring a stable and uninterrupted power flow is also particularly important in safety-critical environments such as hospitals and public security buildings, where electricity is needed to perform life-saving tasks.

However, there are significant challenges to meeting this demand. One of these is the necessity to prep cables correctly, using the right tools and implementing best practices to ensure that work is carried on safely and accurately, and that the result is long-lasting.

Precise cable prepping

When building new power lines, one of the most fundamental parts of the job is the necessity to join cables together and to terminate them to equipment, or to overhead or underground lines. For power networks to operate reliably in the long run, it is critical that this work is carried on with the utmost accuracy, by experienced personnel using the right tools.

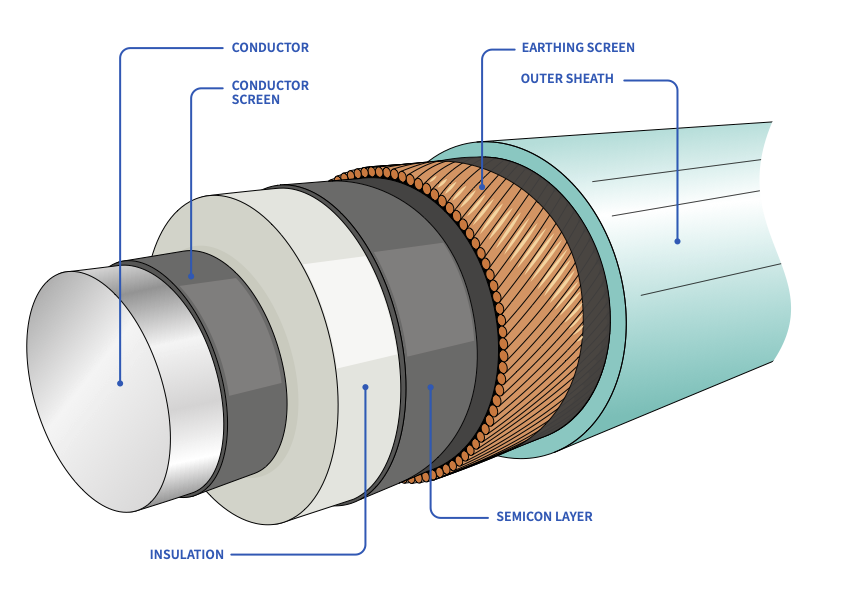

When prepping single-core medium voltage (MV) cables, contractors and linemen need to be able to handle a wide variety of components and materials, from removing the outer jacket, to carefully scoring the semiconductor layer to expose the insulation material.

This type of work should never be done with unguarded knives, and it is essential that linemen and contractors use dedicated tools where the blade depth can be precisely regulated. This will ensure that jackets are cleanly removed and that the innermost layers of the cable will not be damaged in the process.

Spotlight on safety

Another reason to invest in high-quality tools and avoid the use of generic unguarded knives is the safety of operators. According to Lineman Central, power line workers have one of the most dangerous jobs in the US, after loggers and manual laborers in agriculture.

The combination of high voltage power and working at height makes this profession especially risky, leading to a high number of accidents. Storm recovery, in particular, can be one of the most dangerous aspects of the job, as the weather conditions make for an unpredictable working environment and unsteady footing.

Having the right tools and training to work with power cables is of the utmost importance to ensure safety and reach a zero fatalities working environment.

Removing outer sheathing

Prepping cable ends correctly is a prerequisite for a long-lived and well performing power network. Using dedicated tools will make this job easier, faster and safer, and will prevent errors that would compromise the efficiency of the overall power system.

For this kind of work, it is often necessary to remove the outer PVC or polyethylene jacket of a cable to expose the neutrals underneath. In this case, one of the most versatile tools to use is an adjustable cable stripper, such as Ripley’s Infinity US01 or WS64 Series. These strippers can remove jackets and various types of insulation materials on primary and secondary utility cables, eliminating the need for a traditional – and dangerous – stripping knife.

Another handy tool is our US16 Utility Tool, which can remove outer jackets on MV cables with the assistance of a powered speed drill. Thanks to its ergonomic, self-feeding design and micro-indexing blade control, the US16 provides safe, clean jacket removal while protecting the underlying layer.

To assist in the removal of outer sheathing from larger cables, you can also use a slitting tool such as our US15 Large Format Cable Slitter, which has been especially designed to perform slit, ring and spiral cuts on cables with a diameter between 10 and 60 mm.

Removing the semi-conductive screen

To remove the semiconductor layer, or semicon, it is crucial to use a tool that will not cut into the insulation layer, an error that would almost certainly lead to failure due to damage to the underlying insulation. The technique is to make spiral or longitudinal cuts that are (slightly) less deep than the semicon’s thickness, which allows for it to be removed in one or more strips. Once peelable semicon has been scored, our RFNP pliers are perfect for lifting the end to then peel the semicon from the insulation.

An essential step before starting this process is to set the cutting depth of the blade to the appropriate length, which is why it’s important to use precision scoring tools. Scorers from our SCS Series are perfect for the job, as they can precisely score the semicon layer without damaging the insulation. These scorers can accommodate cables with a diameter between 8 and 51 mm, while larger cables, between 45 and 75 mm, can be handled with our SCS MAX Series. For cables that require shaving for bonded semicon, US02 is the perfect solution.

Insulation can be cut back to expose the conductor using a tool such as the WS5 Series WS6 Series or the versatile US01. Finally, most applications require the cable edge to be chamfered, or tapered, to remove sharp edges and avoid the risk of air pockets. In this case, our US10 Cable Insulation Chamfering Tool is perfect for the job, thanks to its sharp blade, delivering a smooth chamfer. Its adjustable clamping system can be quickly and easily locked onto the insulation, providing a stable and precise clamping platform in any space.

By using the right tools, lineman can prep cables safely and accurately, while playing a central role in helping our society move towards electrification and away from fossil fuels.

¹ https://www.eia.gov/outlooks/steo/

⁴ https://www.linemancentral.com/lineman-positions/how-dangerous-are-power-lineman-jobs