Tools for Towers – Top to Bottom

13th March, 2024

Communication infrastructure is constantly changing, and technicians need their tools to keep pace. From the growth of small cell sites, increasing use of hybrid (copper-fiber)

Navigating the digital divide

Today’s world is a digital one. Whether it’s talking to friends on social media, watching a favorite show on a streaming platform, paying bills, ordering goods, or making video calls as part of a job, we all depend on reliable and fast internet connections.

As such, the demand for broadband – enabling greater connection speeds, performance and consistency – continues to grow, with broadband helping deliver economic growth, stimulating innovation, and creating new jobs.

In the US, the Biden-Harris Administration’s Internet for All initiative will invest $45 billion to provide affordable, reliable, high-speed internet for everyone in America by the end of the decade¹. Meanwhile, in the UK, the Government’s Levelling Up white paper has set an ambitious target for gigabit-broadband, with an aim of nationwide coverage for at least 99% of premises by 2030². In Western Europe, broadband penetration has steadily increased during the last decade, and is expected to reach almost 90% by 2030³.

Fiber optic cabling has a key role to play in delivering on these ambitions. The advantages of fiber optic cable are numerous. When compared with traditional broadband, optical fiber cables enjoy less interference and maintain stronger signal strength over greater distances, while operating at a higher frequency, achieving greater bandwidth and faster connection speeds as a result.

But there are significant challenges to meeting this demand. From the scale involved – many rural or urban areas in the US have limited or no access to broadband, with 12% of Americans currently without a home broadband connection⁴ – to the fact that modern cables can now contain thousands of fiber strands, delivering on these goals is a balancing act between speed and precision.

In order to meet this requirement, a fiber optic engineer needs to be equipped with the right tools and training to undertake this critical task. Cable preparation work needs to be completed at pace, while ensuring accuracy, cleanliness and testing is never compromised.

The anatomy of a fiber optic cable

When prepping fiber optic cabling, a fiber optic engineer needs to feel confident and assured they have the right tools to hand, every time. With customer expectations and demands to meet, installers require tried and trusted equipment that enables them to perform their jobs safely and to the highest possible standards. Whether it’s cutting, stripping, scoring, splicing or connecting, technicians want the peace of mind of tools that will allow them to complete a job in a simple and fast manner.

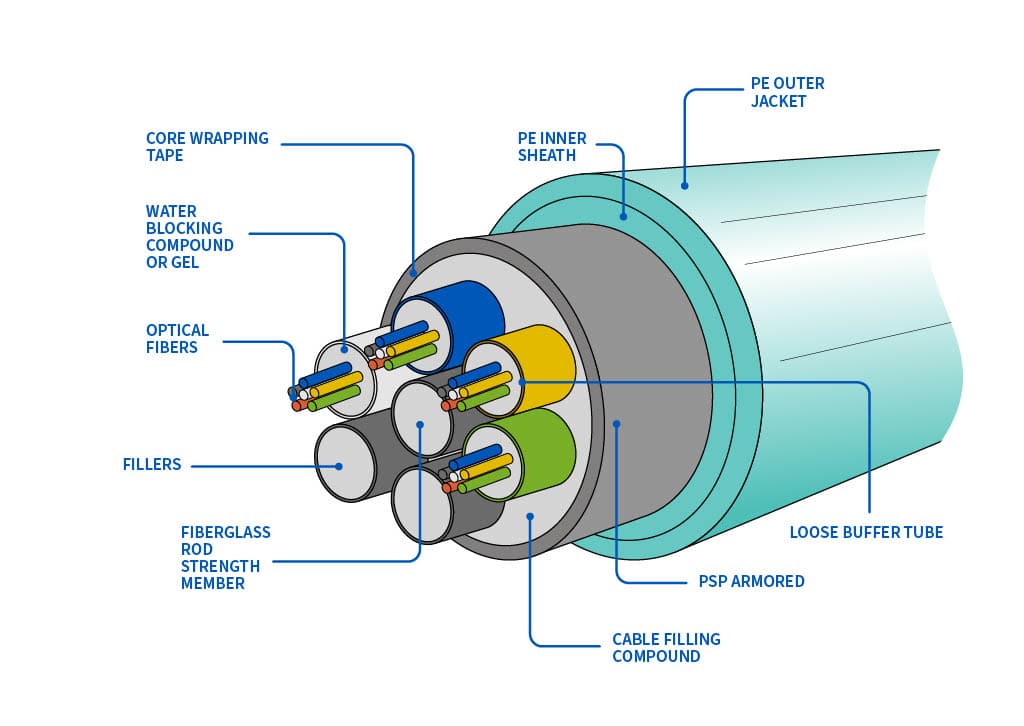

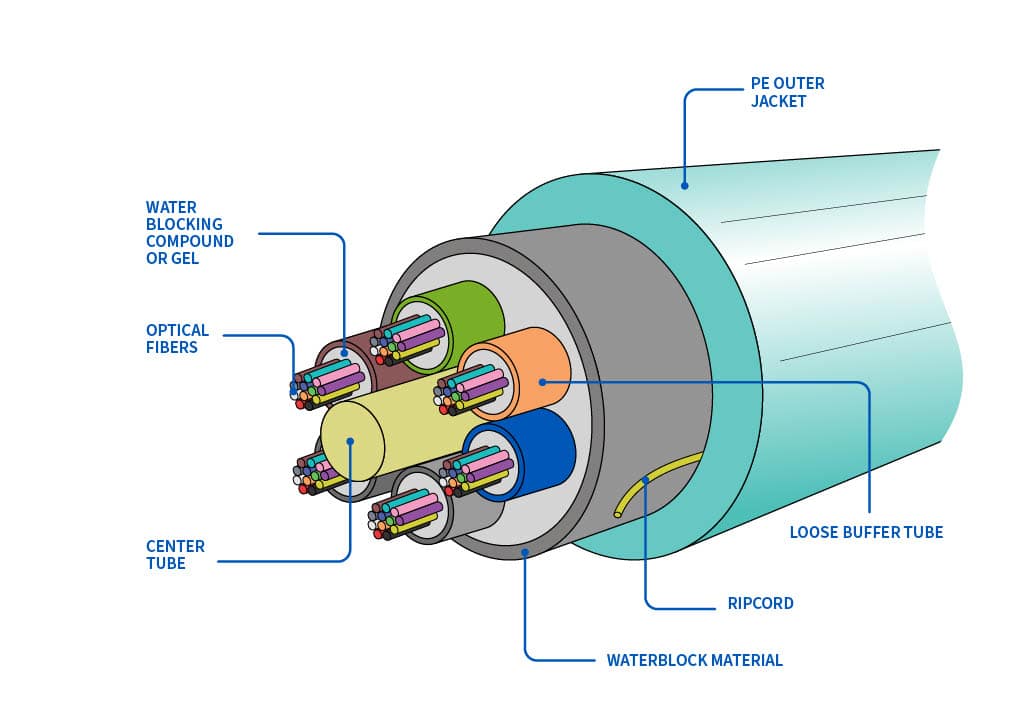

Engineers have to handle a range of components when prepping optical fiber cables. From carefully removing the polyethylene outer jacket and inner sheath and PSP armor, protecting against moisture and abrasion, to ensuring a fiber strand is clean in preparation for splicing, you can see all the components contained within a cable in the illustration below.

Pushing broadband boundaries

There are a range of easy-to-use, efficient and safe tools that are recommended for cable preparation projects. Our Miller® FTS buffer tube scorers are designed to be incredibly easy to use, allowing quick access to loose buffer tubes up to 6mm in diameter. Simply press the tool’s halves together to open it, and then place it at the desired strip point. Then, rotate the tool a couple of times to create a score. If done correctly, this will provide clean access to the fibers below with no damage.

Meanwhile, the market-leading MB02 series makes cable access faster, easier and safer for engineers. The multi-purpose precision slitter features a modular tray design for work on various dielectric cables. With a range of inserts available, trays are color coded and magnetic, making them easily swapped out to accommodate accurate blade depths and cable diameters, providing unrivaled flexibility. Performing accurate ring and longitudinal cuts on dielectric cables of up to 0.79” (20mm) in diameter, the MB02 series should be a mainstay in any engineer’s toolbox when working on optical fiber cables.

Another recommendation is the MSAT-X from Miller®, a versatile shaving tool for gaining mid-span access to bare or buffered fiber cables. Equipped with a unique spring-loaded plate and dual stripping channels, the solution lets a fiber optic engineer load 1.9 to 5mm diameter cables into the same cutting blade, without a sizing gauge.

There’s also the CFS-3 series fiber optic stripper. Featuring a three-hole design, this efficiently removes fiber jackets and buffers, sized between 1.6mm and 3mm, down to the 125 micron bare fiber in one compact tool.

It’s also critical to ensure fiber strands are clean, as oil, dust and dirt particles can result in attenuation. Fiber inspection microscopes from Miller® are recommended, so an engineer can check an endface for faults. And with fiber optic networks reliant on the correct light connections in order to function correctly, a visual fault locator like the FO-VFL series can help a fiber optic engineer quickly find fiber breaks, leaks, stress points and faulty connections. With so many fiber strands contained within a cable, identifying faults fast is absolutely essential.

By following these steps, fiber optic cable engineers can perform their jobs to the highest quality and safety standards, while playing a critical role in helping the world move towards its ambitions for faster, stronger broadband.

¹ National Telecommunications and Information Administration, ‘Biden-Harris Administration launches $45 billion “Internet for All” initiative to bring affordable, reliable, high-speed internet to everyone in America’, https://www.ntia.doc.gov/press-release/2022/biden-harris-administration-launches-45-billion-internet-all-initiative-bring

² UK Parliament, House of Commons Library, ‘Gigabit-broadband in the UK: Government targets and policy’, https://commonslibrary.parliament.uk/research-briefings/cbp-8392/#:~:text=The%20Levelling%20Up%20White%20Paper,85%25%20of%20premises%20by%202025.

³ S&P Global Market Intelligence, ‘Breaking into Europe’s Digital Infrastructure Markets: Drivers and Trends’, https://www.spglobal.com/marketintelligence/en/news-insights/blog/breaking-into-europes-digital-infrastructure-markets-drivers-trends-3